What can go wrong with your Car Air Conditioning.

Initially the system is charged with sufficient Refrigerant (gas) to fill the evaporator when the system is operating. The compressor has an electromagnetic clutch which when engaged starts the compressor pumping refrigerant around the system.

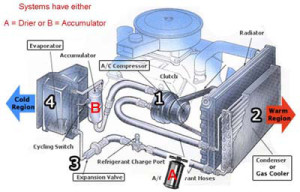

The refrigerant is pumped into the condenser (usual in front of the radiator) then usually through the Receiver Drier (filter) up to the TX Valve with an orifice which restricts the flow of the high pressure liquid. At this point the orifice allows some refrigerant to escape into the evaporator (usually behind the dash) as a low pressure cold vapour.

Simply put, heat will always be attracted to cold so the heat in the air passing through the fins of the evaporator is attracted to the cold and is moved with the vapour back to the compressor and in so doing reduces the temperature of the air inside the car. There are resistors that regulate the speed of the fan moving air through the evaporator.

The cycle continues with the compressor pumping the high pressure/temperature refrigerant back through the condenser. Air is forced through the fins of the condenser either by a fan or the forward movement of the vehicle. This air is not as hot as the temperature of the condenser and as heat is attracted to cold the heat extracted from inside the car by the refrigerant, now in the condenser, is dissipated into the atmosphere outside the vehicle.

There are pipes and flexible rubber hoses (allow movement) connecting all these components all of which have sealing O-rings at the joints. The compressor crankshaft is a moving part and has a special seal to prevent refrigerant from escaping. There is a thermostat that controls the compressor clutch to regulate the temperature inside the car and a pressure switch to regulate the condenser fan. There are also safety switches to protect the system from damage caused by excessive pressure and/or insufficient refrigerant.

So the system can lose some or all of the initial refrigerant charge through wear or deterioration of any of the hoses, Orings, gaskets and seals as well as damage to the condenser or Evaporator. The hose also won’t completely contain the refrigerant which does permeate out at low rates all the time.

The compressor can wear and underperform or even seize up. The Field coil in the electromagnetic clutch can develop an open circuit (burn-out) and won’t work. Some compressors are Variable Stroke type and can destroke (spin but not pump).

Any of the electrical pressure switches, thermostats, resistors or fan motors can fail.

The TX valve can become restricted and reduce the flow of refrigerant. This can also reduce the flow of oil back to the compressor causing it to seize.

A Re gas is not always the solution. Contact Us Now!